Getting your Trinity Audio player ready...

Although it landed on Intel Israel’s two CEOs, Daniel Benatar and Karin Eibschitz-Segal, less than a year into their jobs, they both have extensive experience at the international micro-chip giant under their belts. They embarked on their careers at Intel as students. She started out 21 years ago as a Computer Science student at the Technion and 30 years ago, he was a Physics and Mathematics student at the Hebrew University.

Read more:

This year, Intel marks (and in the spirit of the time, isn’t celebrating) 50 years of operations in Israel. What started out in 1974 as an office employing five workers in Haifa has become a vast operation with 12,000 employees – 10% of the 120,000 workers Intel employs worldwide. The company operates three large R&D centers in Haifa, Jerusalem, Petah Tikva and a micro-chip production mega-plant in Kiryat Gat.

This is a huge responsibility, especially as the canons are roaring. “The war caught me on vacation with my family in Eilat,” says Benatar. “Everyone was shocked. I called Karin at 7:30 am. We both realized immediately that this was very big. It was enough for us to see those pictures of the pick-up trucks inside Sderot. Intel has so far lost two employees in Swords of Iron. Family members of five more employees have been kidnapped to Gaza and 450 workers are still evacuated in the north and south of the country. Over 1,500 people - 15% of the company’s employees were called up for reserve duty.

Karin: “Our priorities are always clear in situations like this – our workers’ safety and security always come first. We knew we had lots of people living in the south of the country, including in the Gaza Envelope, as well as many in the north. In the very first hours of the war, we set up a kind of war room. We also held a video conference with all the operations directors in Israel and we kept in touch every couple of hours.”

Daniel: “At 4 pm we got Intel CEO Pat Gelsinger in the United States onto a video call. He was concerned and trying to understand what was going on. I then suddenly noticed that Kiryat Gat is only 20 miles from Gaza, and on a world map that looks especially close.

“Functional Continuity” is very important in global companies. I understand that at times like this, it’s important to show that things are under control, that everything’s working.

Karin: “Of course. These kinds of things are hard to deal with in an emergency if you’re not prepared. We obviously weren’t expecting October 7, but our sub-organizations always have routine plans for emergencies. During those first days, I think everyone in the company was aware of the special importance of maintaining Intel Israel. It’s an enormous responsibility. The war has various channels and the military channel is just one. The economic channel is also very important, and we know that Intel plays an important role in the country’s economic strength. It’s responsible for 5.5% of hi-tech exports and 1.75% of the country’s GDP.

“It hasn’t been easy. Those who weren’t recruited for reserve duty were evacuated. We have mothers left on their own with children, parents of soldiers, etc. and they’ve all got their own reasons for being stressed out. But everyone’s made a huge effort to do their bit, to give that bit more. We have no fewer assignments, and we haven’t asked for that. And no one’s cutting us any slack.”

The world's toughest people

Only a month ago, at the height of the fighting, as the pressure was on for the giant Silicon Valley hi-tech companies to publicly condemn Israel, Intel announced an unprecedented $25 million investment to set up Fab 28, a new chip plant in Kiryat Gat -considerably expanding the plant that started construction back in 2021. The investment, coming at the company’s hardest ever time in terms of business, brings the sum volume of investment in Israel to $50 billion. This is the country’s largest construction project, sitting on an area the size of several football fields and is set to employ thousands. A concrete manufacturing facility has been raised at the site itself to ensure concrete trucks don’t block the entrance to Kiryat Gat. The world’s second-biggest crane – the largest in Israel, lifting 2,800 tons at a radius of 165 feet - has also been installed.

Fab 28 is the company’s largest investment in Israel. It’s also signed off on three of the ten largest exits of Israeli companies ever: Mobileye at $15 billion in 2016; Habana Labs which was bought for $2 billion in 2016; Moovit that Intel acquisition in 2020 for almost $1 billion, along with a further acquisition amounting to almost $20 billion over the past decade. The $5.4 billion acquisition of Migdal HaEmek-based chip manufacturer, Tower Semiconductor, fell through at the last minute.

Is this an ongoing love story? Like all his predecessors, company CEO Pat Gelsinger can’t hold back with the superlatives when talking about Israel and the company’s employees. In a Fox interview, he excitedly said “I have 20,000 people in Israel, and I feel responsible for them all.” He continued BY saying “Israelis are the toughest people in the world. Despite the war, they haven’t missed the production of a single silicon wafer or their existing commitments to developing products. That’s why we’ve been there for 50 years.“ During the course of the war, as a sign of appreciation for what he terms “the compassion and resilience you’re displaying,” each employee has received a special $5,000 grant.

Doesn’t this harm Intel’s world business? Iran may give up on its “Zionist processors.” Isn’t Glesinger influenced by the criticism leveled against him?

Karin: ”These are purely business decisions and we come with proven results. Globally, Intel Israel provides enormous value to Intel. We have a clearly defined role in this respect. We must constantly bring significant business and technological value. This way, only business considerations will win. I see our role as leading Intel Israel so that there is no question at all about the global value we bring to both the company and the semiconductor industry.”

Was anything in the company’s schedule or planned assignments nonetheless affected by the war?

Karin: “No. People really worked above and beyond to cover deficiencies. It’s a double issue - both the role Intel Israel plays in Israel and its function in the world company. It’s in no way trivial and it’s critical we sustain it.”

Daniel: “Anyone working in Israel at Intel knows that they’re not just working for the pay. Everyone has a broader picture of the place Intel holds in Israel. We also show our employees that we care. We’ve been very flexible about their needs.”

Where do things stand now?

Daniel: “Over half of those recruited are back from reserve duty. Their reentry hasn’t been easy. They come with baggage. Evacuees from the north and south aren’t back at work normally yet. We ‘tailor’ solutions for each worker.”

Karin: “We’ve conducted a lot of training for managers on this front, teaching them how to deal with the situation and create flexible solutions.”

There are no free lunches in business. In exchange for this large investment, the government will grant Intel an unprecedented incentive package of almost $3.2 million spread over several years. It would be hard to believe that this was the deciding factor for the investment. So, what was it? Intel both develops and manufactures the chips. The most brilliant minds are responsible for the company’s R&D at its groundbreaking laboratories crowning the company queen of its field – at least until the crisis of recent years. Chips designed in Haifa have been driving computers and devices across the globe, and the investment in the Kiryat Gat manufacturing plant has proven itself profitable and, over the years, has stood up to challenging tests.

Why does building a plant like this take 4-5 years? And why does it cost so much?

Daniel: “It takes a year, maybe a year and a half to build a regular residential building. In one go, we’re building a project equivalent to thousands of buildings. Planning involves 5000 contractors from various fields. It all needs to be precise and coordinated. The plant can’t be affected by shaking. Complex systems transporting gasses, chemicals, water and electricity will pass through the plant.

"The construction alone costs billions. Intel Kiryat Gat will reach the same scale as Tel Aviv in terms of electricity and water consumption. Planning and implementation are being carried out for Intel by a global company that also plans our other plants. The actual construction is mainly being conducted by Israeli companies. As we’re currently also building in Arizona and Hawaii, and soon Germany, to keep costs down we’re trying to ensure the planning is similar."

The huge grant that Intel receives from the Israeli government for setting up the plant has been met with criticism. Some economists are saying that Israel has become addicted to Intel and that putting all of the country’s eggs in one basket for 50 years is dangerous. Some further claim that your promise to provide work for Kiryat Gat and the surrounding area is questionable as most of the workers are bussed in from outside the city.

Daniel: “At the Kiryat Gat plant, 68% of the employees live in the south of the country. By the terms of the agreement with the government, Intel is committed to purchasing raw materials from small to mid-size suppliers in Israel to a value of – wait for it – 60 billion NIS over the next decade. Presently, 1,500 of our suppliers are from the area. Just think about what that does to the area supporting the plants – restaurants, car-servicing companies, cleaning contractors, etc.”

“As CEOs, we have a real social commitment that’s reflected in our connections with the country’s universities, regional councils and the special projects we’ve launched and those with which we’re partnered. Take our social college, Ofek Darom. We employ practical engineers and people with Masters and doctoral degrees. Three years ago, when I was still just the Kiryat Gat plant CEO, we decided to employ workers from the south of the country from Sderot, Ofakim, Kiryat Gat and Kiryat Malachi hailing from difficult social and economic backgrounds.

"This entails 150 men and women who had not graduated high school. We made them fully-fledged Intel employees. Selected by their levels of motivation, they sat in classrooms at Intel Kiryat Gat for nine months as our engineers taught them Mathematics, English and Robotics. They were trained as practical engineers in the 'clean room' where the chips are made.

“It’s hard to describe what it does for these people. It’s much more than a paycheck and making a living. Their partners suddenly want to work at Intel and their children become interested in Mathematics. The city mayor called me to complain that my employees were walking around the supermarket with their Intel tags on making everyone jealous.”

“This was three years ago. Only a handful of the 150 have remained. They’re excellent workers. This year, 60 of them began studying toward becoming engineers – and Intel’s footing the bill. They have two days’ study each week and they work the other three days. When the new plant is built, we’ll recruit another 500.”

Karin: “I always say that the Hebrew word 'hevra' means both 'society' and 'company' in English. So, we’re responsible both to Intel, the company and to Israeli society. We do a lot to integrate various sectors of the community: Intel is Israel’s largest employer of workers from the Arab sector, and we employ a lot of ultra-Orthodox women, mostly in Haifa and Jerusalem. At the Kiryat Gat plant, we also employ young people on the spectrum.”

“But there are two further important elements: The semiconductor industry is critical for Israel as a country. It’s been said that, in the coming 50 years, silicon will replace oil as the major resource. Furthermore, we know that Intel constitutes an engine for growth for the entire ecosystem within Israeli society. In addition to our collaborations with universities, dozens of companies have been created here by Intel alumni.”

Just this week, it was announced in the United States that Intel has decided to delay setting up the plant you mentioned in Hawaii at an investment of $20 million. I’m seeing warning signs. How can we be sure that won’t happen here?

Daniel: “The global market is very dynamic, but when it comes to investments on this scale, starting the process is good news. It means that, even with delays, it’ll happen in the end. It’s a market expected to double itself by 2030 to generate $1 trillion. Intel must be prepared for this. So, if there’s a delay of a year or two, it’s a matter of necessity.”

Atomic miniaturization

Eibschitz-Segal, 45, married and mother of two and Benatar, 58, married with three children, had served in key roles in world Intel before being appointed CEOs in Israel, and continue these responsibilities today: Benatar is also joint CEO of all Intel’s production plants across the globe, including those in Israel, Ireland, Germany, Arizona, Oregan and Ohio. Eibschitz-Segal heads Intel Validation Engineering, responsible for checking personal computing products and servers before they hit the market. They both proudly carry the global company’s title “Executive Vice President.”

Benatar was born on Moshav Beit Nekofa in the Jerusalem hills. As a child, he dreamt of growing plumbs and remaining a moshavink. He's known for turning down interviews. He has a fear of heights - and the job requires a lot of flying. Eibschitz-Segal was born in Haifa and with a mother, father and sister who are all doctors, is a bit of an odd duck in the family (“They test me on drug names at mealtimes”).

Do any other Intel centers have two CEOs?

Karin: “No”

So, apart from internal politics and respect, why is this? You each represent a different part of Intel – Karin R&D, and Daniel production.

Daniel: “That’s exactly why we’re both here. We very much wanted to bring R&D and manufacturing closer and link the two. I don’t think I could do it with Karin. It’s not about egos.”

Karin: “I think we work very well together, both on personal and organizational levels. It allows for cooperation between the two fields. Intel has never had such strong cooperation in addressing challenges.”

“Challenges” is a soft word to describe the turmoil Intel has gone through over the past two years. The company, which for decades has dominated the global processor market, has taken blow after blow. The advent of recovery was only registered last week with the publication of positive reports for 2023. It started with the global Covid pandemic contributing to a crisis in the company’s flagship field of computer processors. After millions worldwide were quick to equip themselves with computers, demand dropped in an instant.

Then, delays in transitioning to manufacturing advanced technologies left Intel lagging behind. The company, negligently, missed the cellular processing markets years ago. AMD and Nvidia have been fighting the battles in the graphic and server processor markets without Intel. Companies such as Apple and Google gave up on Intel’s services and developed their own “personally-tailored” processors for various purposes using technology different from Intel’s. And as if that wasn’t enough, Qualcomm has recently overtaken Intel in the field of wireless communications components.

Intel has definitely paid a huge price for lagging behind its technological rivals following a series of managerial failures and poor decisions. CEO Glesinger decided to shake things up and drew up an ambitious multi-year plan that includes opening its plant gates to anyone interested in creating chips (the Foundry model) – a market valued at over $100 million.

Let’s talk about the elephant in the room: Intel today isn’t what it was five years ago. How will the company get itself out of this?

Karin: “Firstly, I believe competition is good. To lead toward innovation, competition makes you better and it’ll ultimately make us stronger – even if it’s unpleasant and not easy. The phrase ‘Only the Paranoid Survive’ was coined by legendary Intel CEO, Andy Grove. Intel has adopted Gelsinger’s aggressive integrated strategy with four-year targets. At this time, Intel intends to catch up by launching five ‘families’ of products. We’re already on it. We’re in full swing.”

What do you mean by 'family of products'

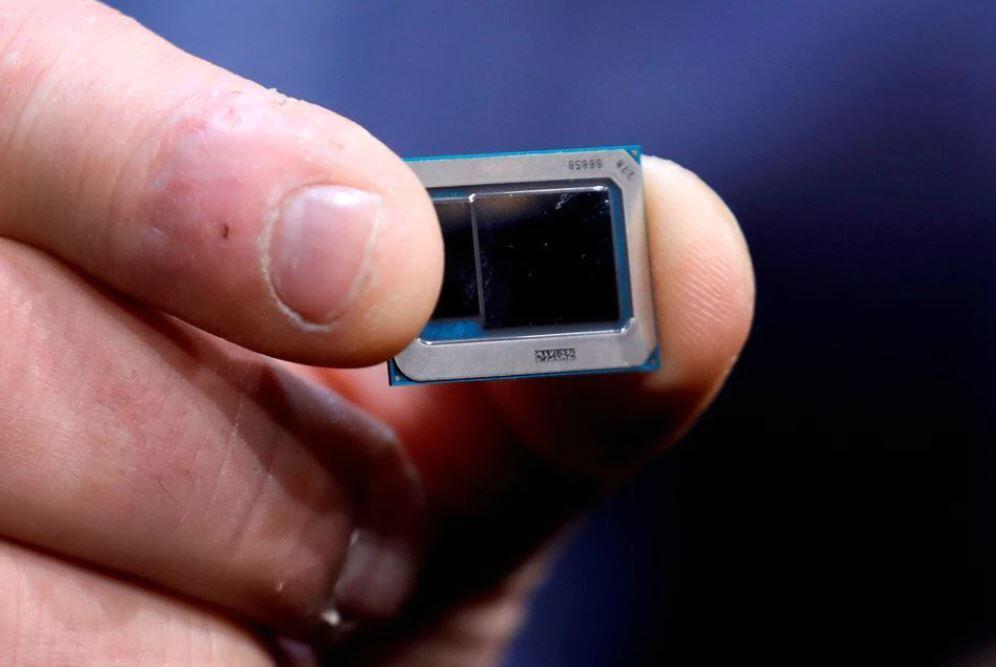

Karin: “These are production technologies of families of processors, like those designed for servers (data centers), or personal computers. These product families are designed to compete with, and be better than, our competitors’ corresponding families. Intel aims to quickly bounce back to our position as the technology processors leader that we lost to the Taiwanese company, TMSC. This year, we will reach miniaturization technology to the level of an atom. We call this Intel A20 and Intel A18 – our answer to TSMC. We’ve already started using the world’s most advanced extreme ultra-violet (EUV) technology – a first for mass production.”

“AI is a further front against our competitors. The market leader is currently Nvidia which has invested years in their artificial intelligence processors and their product is good. Intel will be the only company with a broad range of products allowing to smoothly integrate AI into all possible products.”

“And there’s the Foundry – opening up our production capabilities to other companies, including to our competitors. Presently, only 20% of world chip manufacturing takes place in the West, the rest is mainly produced in Taiwan. Western governments are aiming to reach 50%. The US and European governments have invested a lot of money in this.”

Daniel, you’re responsible for the company’s production centers, and not just in Israel. Isn’t the Foundry concept like an earthquake for you?

“Very much so. Only this week, we signed a contract to manufacture chips with 12 nm technology for a certain company. This means that we now need to open up all our systems and adapt them to the company’s needs. You say yes to anything the customer asks. They can then come along to the plant and find out all your secrets, the professional property you’ve been developing for years. It’s like letting strangers into your home. It’s a complex task.”

So, what are you working on in Israel at the moment?

Karin: “In R&D, we’re focusing on four major fields. In computing - our most important field - we’re playing an important role in Intel’s recently announced 14th-gen processor that includes AI components in a new category of artificial intelligence computers (AI PCs). The 15th-gen processor, developed in Israel - mainly in Haifa – will be a greater leap forward. We’re also working on advancing the Xeon core processor’s capabilities for all data center servers.”

“Another field, that’s relatively stable, is communications. Here we’ve developed components for Wi-Fi 7, that are already part of the 14th-gen processors.”

“AI is also growing and developing, as is cyber – that’s more transverse in that it provides solutions to all other fields and serves our products.”

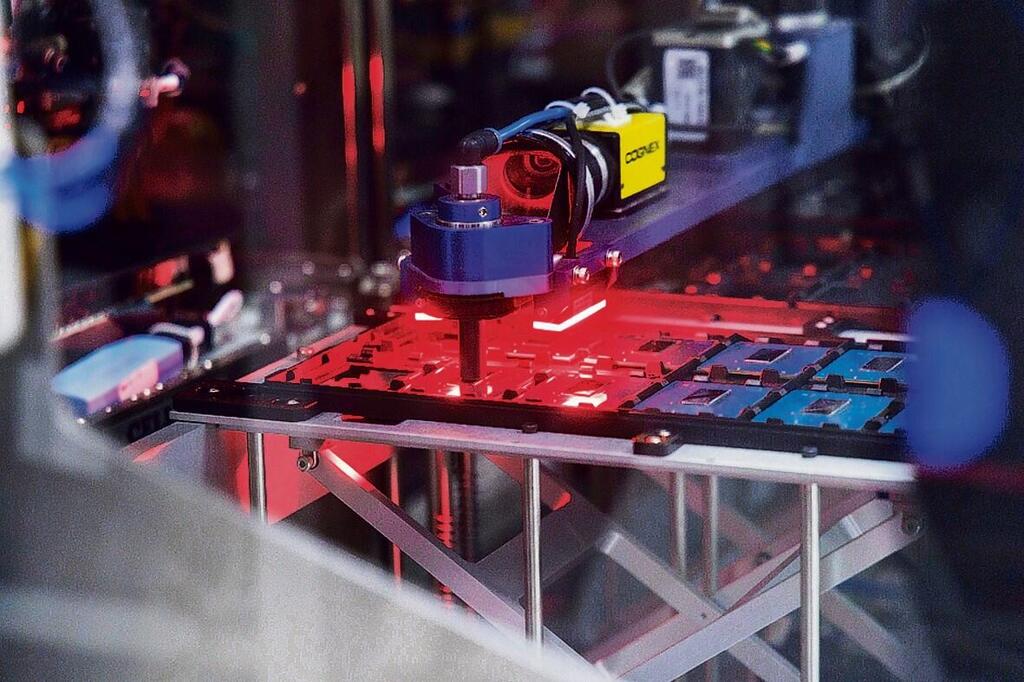

Daniel: “In the Kiryat Gat manufacturing plant, we’re manufacturing what we call the Intel 7 – 10 nm. In the Fab 38, in 4-5 years’ time, we’ll manufacture chips using technology of less than 2 nm with ultra-violet lithography technology. For this, we’re acquiring special machines from the Netherlands, each with a $300 million price tag.”

What are the chips industry’s challenges in the coming years? Are you already planning new chips to come out in 5 years’ time, meaning you have to forecast the needs of tomorrow’s users today?

Karin: “True. It’s already clear that AI use will catch on, so our processors must be leaders in the field. Telling the future involves identifying emerging trends. How much will people be using their personal computers, cellular phones or other devices? How important privacy will be to them, i.e. protecting personal information. These are just examples. “

Daniel: “We also have questions about expected technological progress in coming years. Electricity consumption is one of the greatest challenges in today’s processing fields. We’re constantly trying to decrease consumption while increasing output, always trying to reach the right balance. The challenge is to minimize the transistor as much as possible so that it consumes less current and is faster, while integrating AI.”

Are there really people getting together thinking about what a processor should look like in ten years’ time?

Karin: “Yes. We have people here in Israel specializing in this and defining what we term the general product concept. Then the architects come into the picture. They take the concept and build the initial architecture for it. Only then the design and planning team step in translating the architecture into the final chip."